Please Chooese

Feature

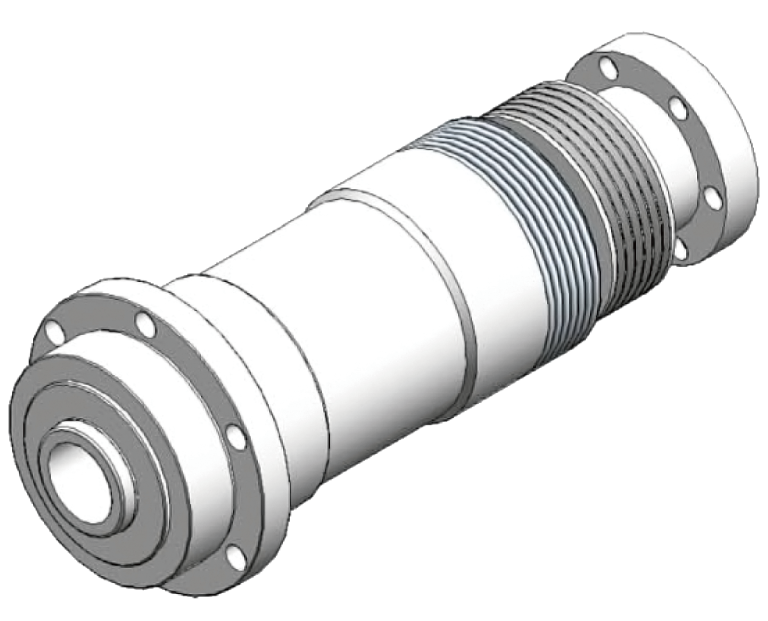

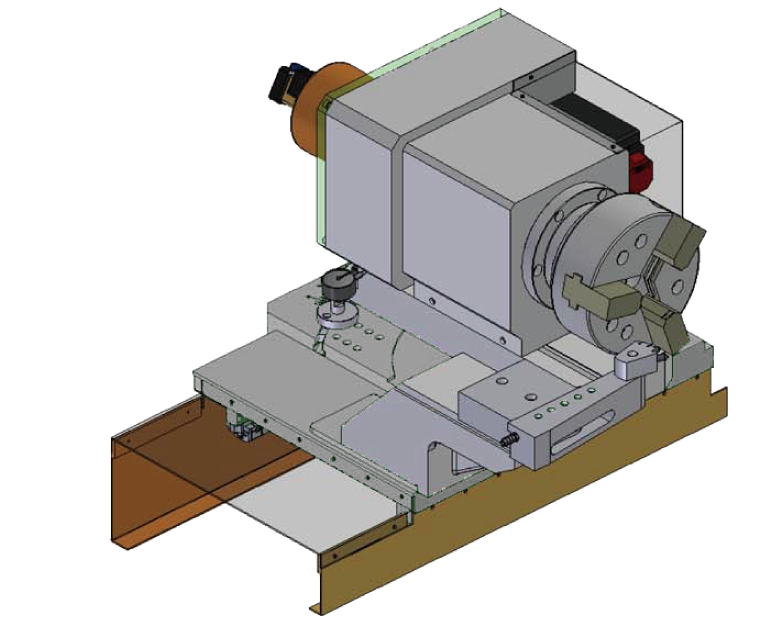

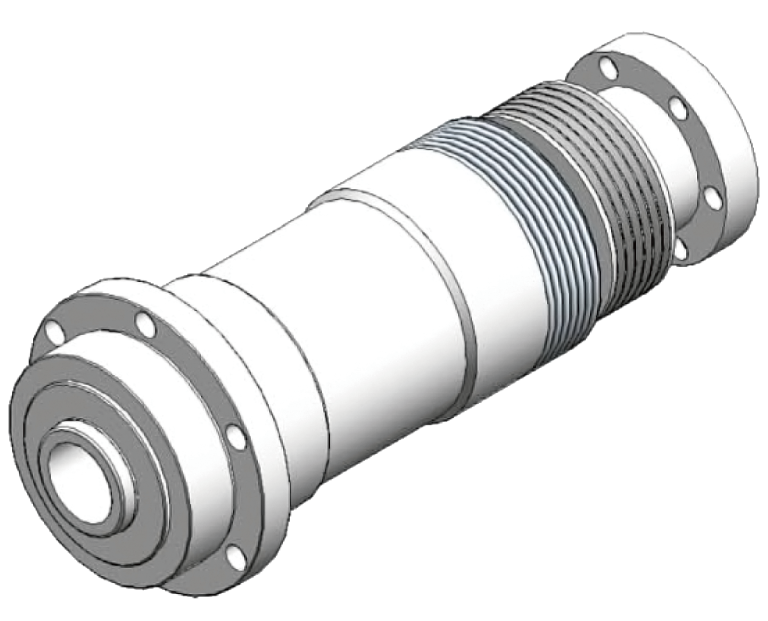

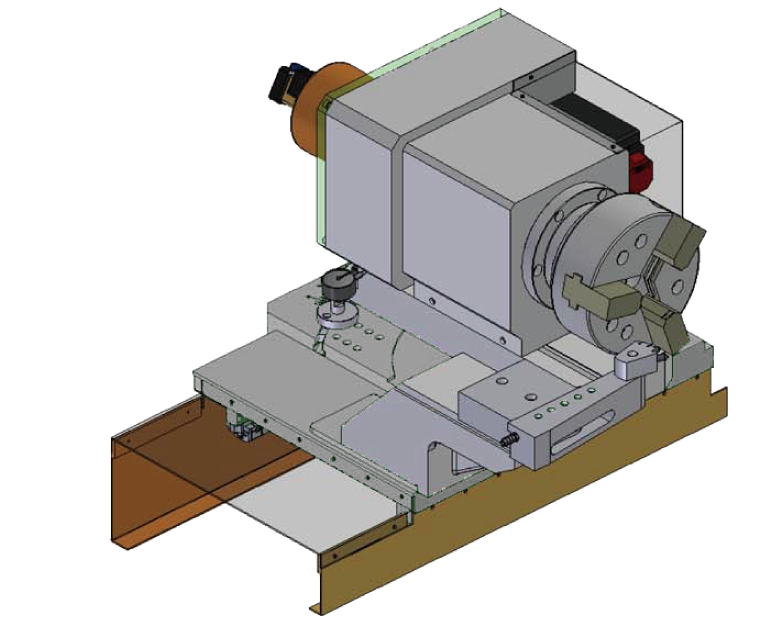

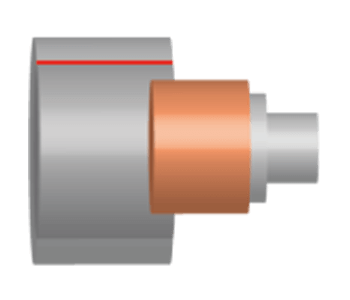

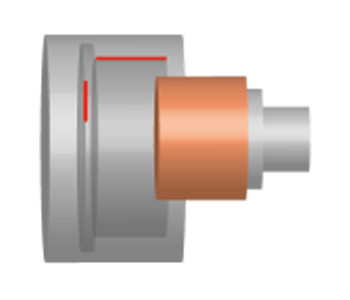

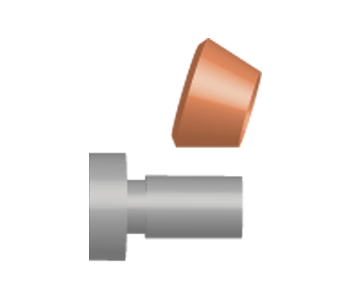

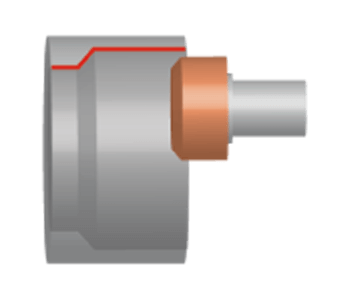

Complete one piece cartridge spindle can avoid the eccentricity of spindle housing and reduces the heat increase for spindle longevity.

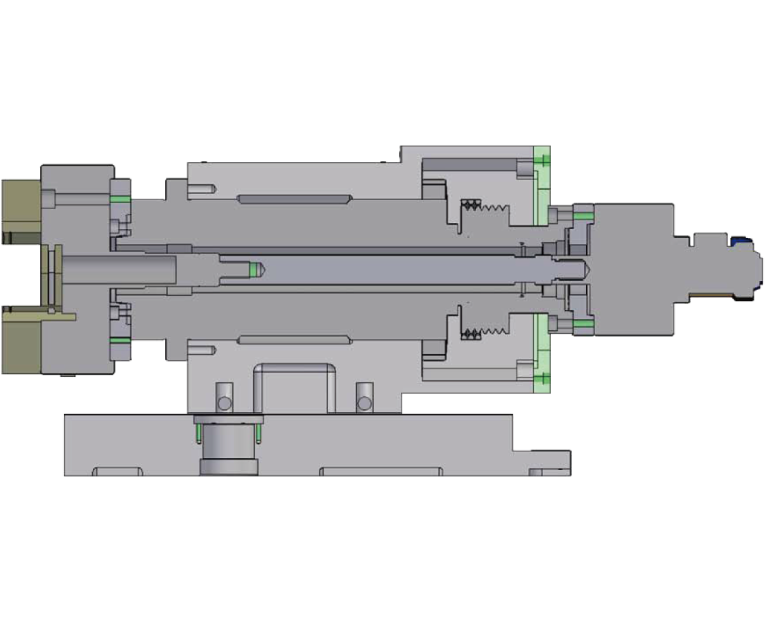

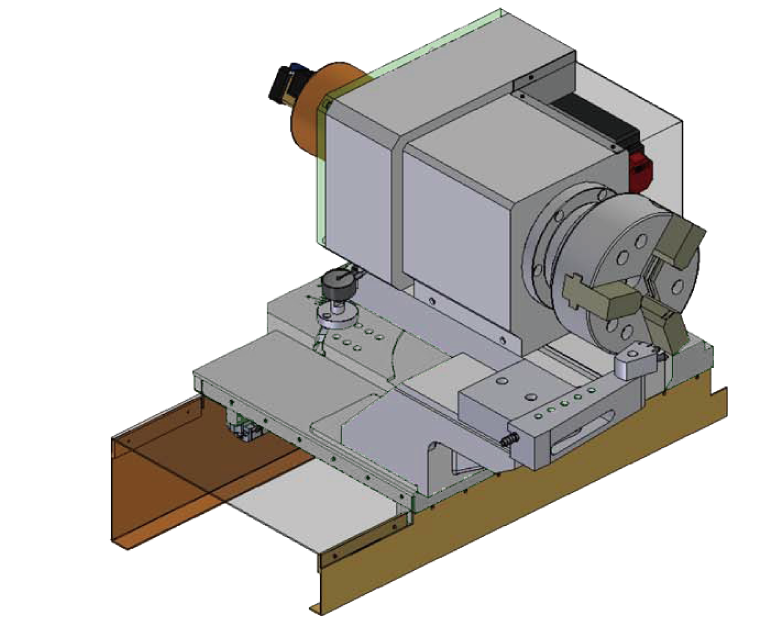

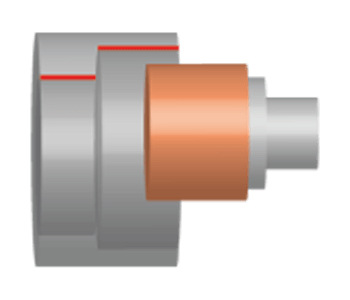

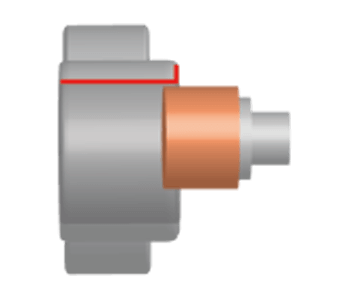

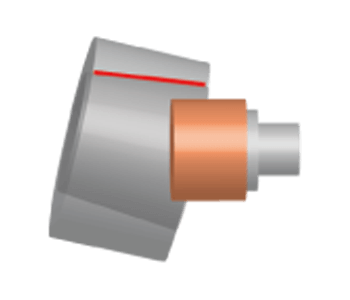

The spindle head design places the center of gravity at the rear portion to help balancing the whole spindle mechanism to increase spindle accuracy and loading capacity.

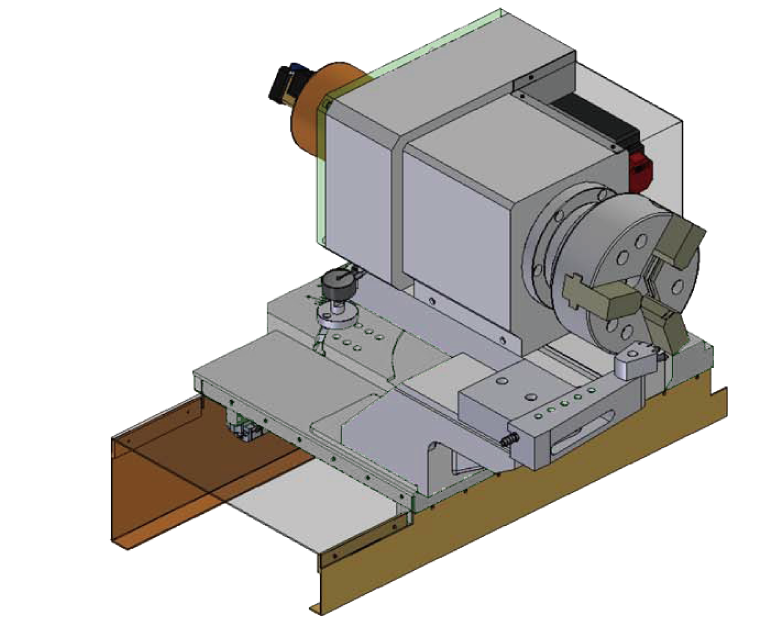

Spindle driven by servo motor offers optimum speed and torque performance.

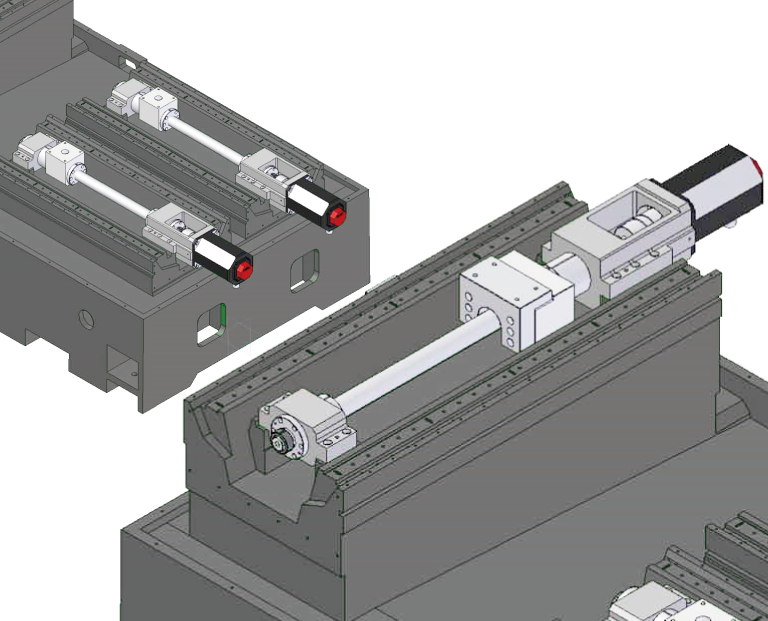

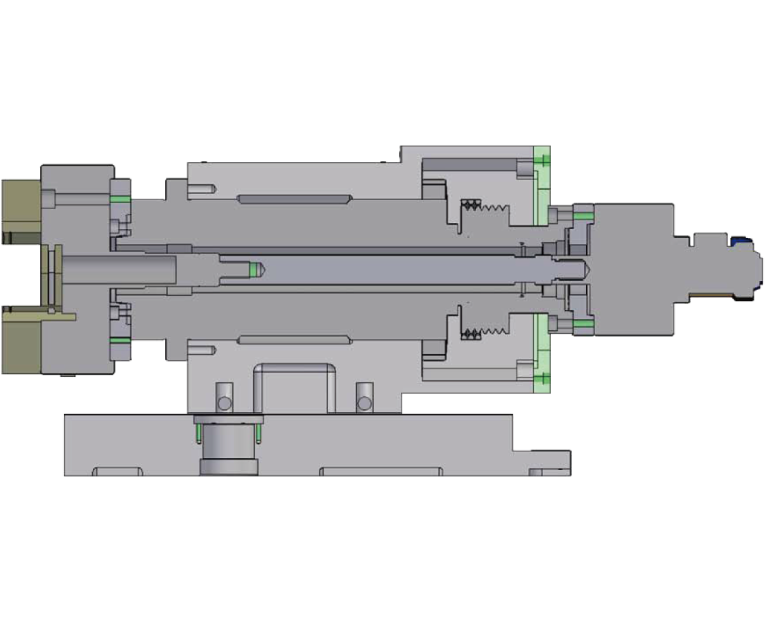

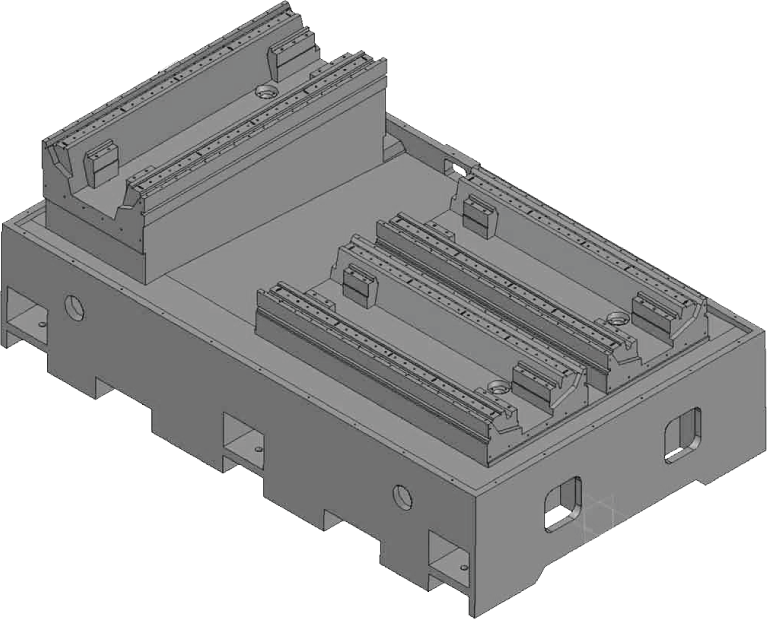

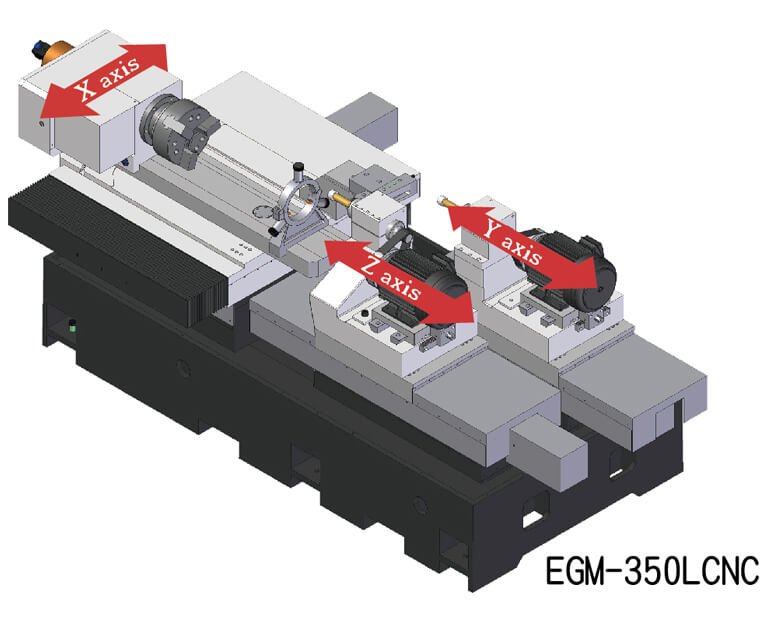

X axis lower slide design offers easy adjustment of the workhead for grinding parts with different lengths.

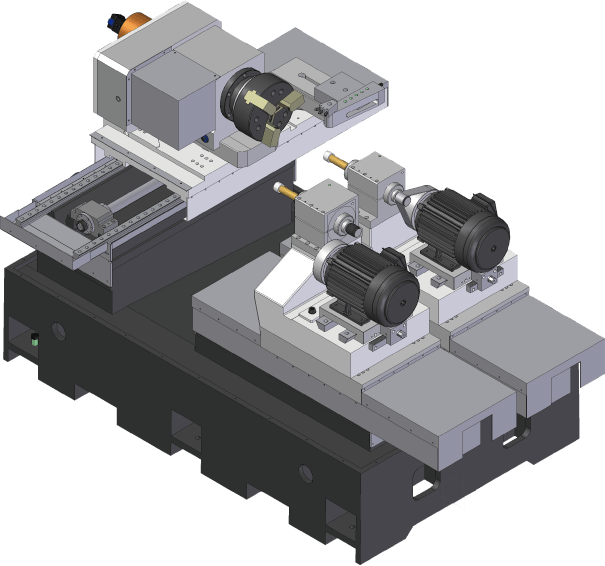

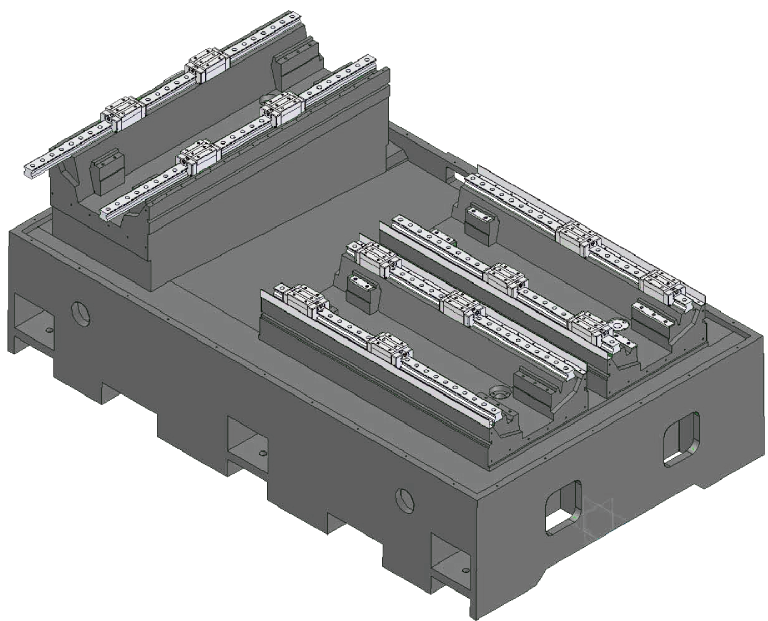

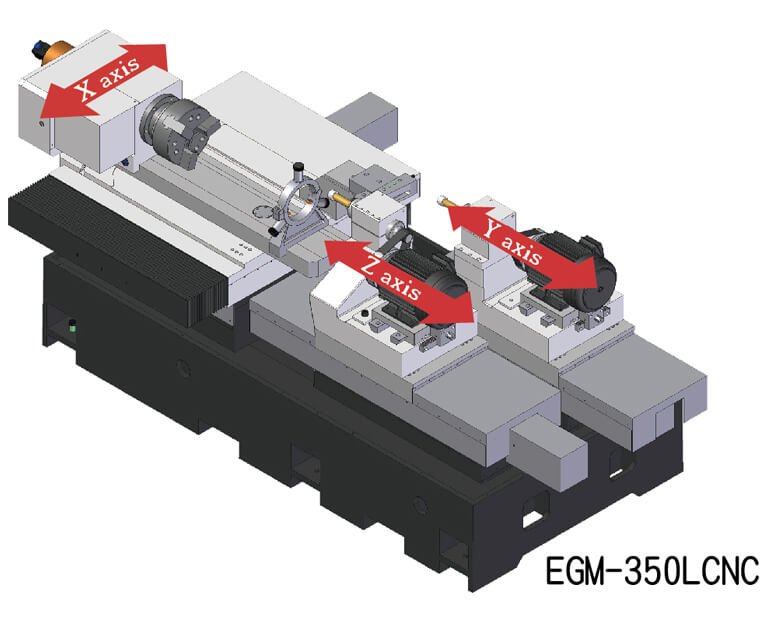

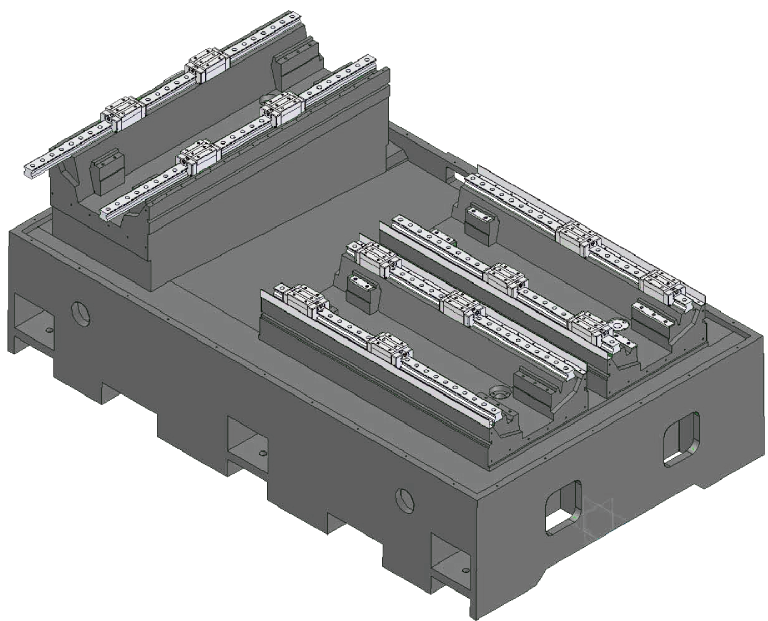

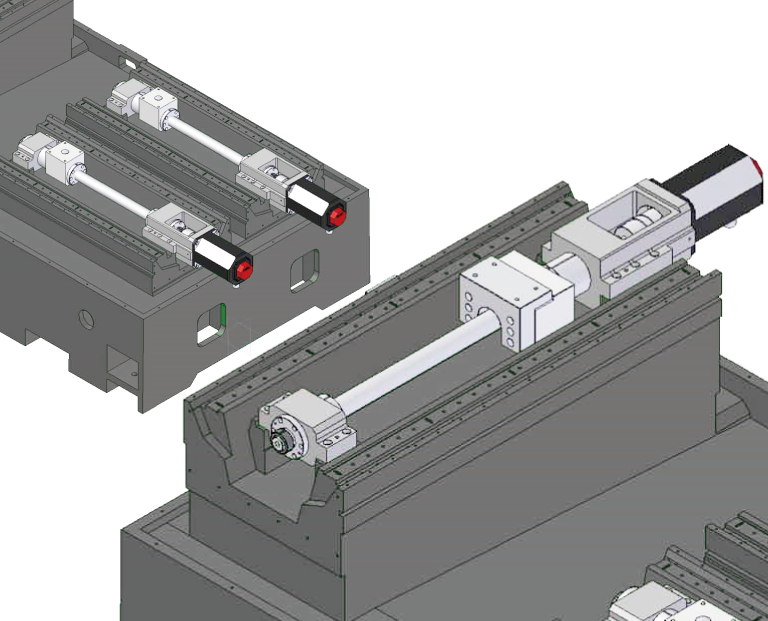

Machine incorporates roller type linear guide ways for X/Z/Y axes for high dynamic rigidity and better loading capacity. This drastically increases the grinding accuracy.

C1 grade precision ball screw with large leading pitch is used to achieve high accuracy.

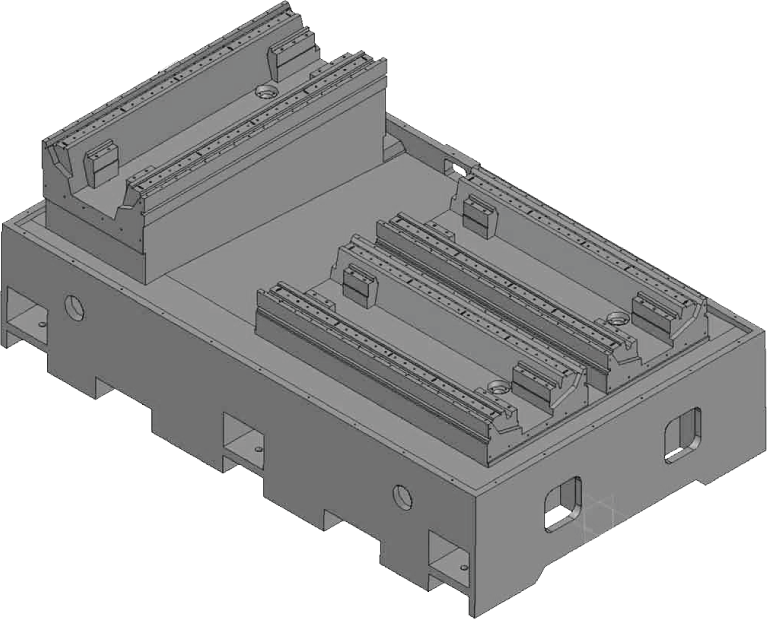

Low-gravity base structure, with slant bed design for better coolant draining and grinding swarf removal.

Complete one piece cartridge spindle can avoid the eccentricity of spindle housing and reduces the heat increase for spindle longevity.

The spindle head design places the center of gravity at the rear portion to help balancing the whole spindle mechanism to increase spindle accuracy and loading capacity.

Spindle driven by servo motor offers optimum speed and torque performance.

X axis lower slide design offers easy adjustment of the workhead for grinding parts with different lengths.

Machine incorporates roller type linear guide ways for X/Z/Y axes for high dynamic rigidity and better loading capacity. This drastically increases the grinding accuracy.

C1 grade precision ball screw with large leading pitch is used to achieve high accuracy.

Low-gravity base structure, with slant bed design for better coolant draining and grinding swarf removal.

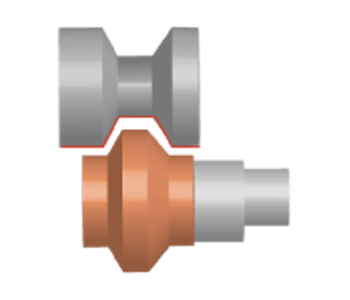

Grinding Example

Standard grinding cycles and multi-steps graphic

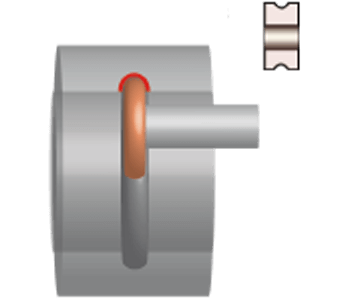

Inner through

2 Step straight hole

Inner through hole + outer end-face

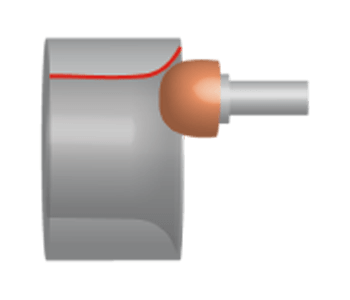

Inner blind hole + Inner end-face

Inner taper

Inner blind hole + ID chamer

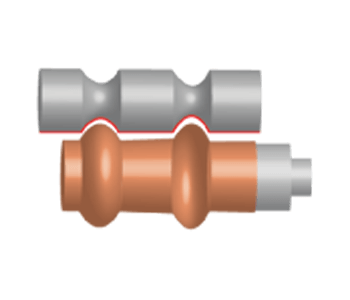

Inner radius groovin

Inner through hole + Inner radius

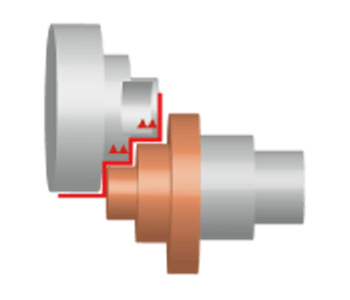

Multi-step grinding

Profile grinding

Form grinding

Specification

Accessories