Please Chooese

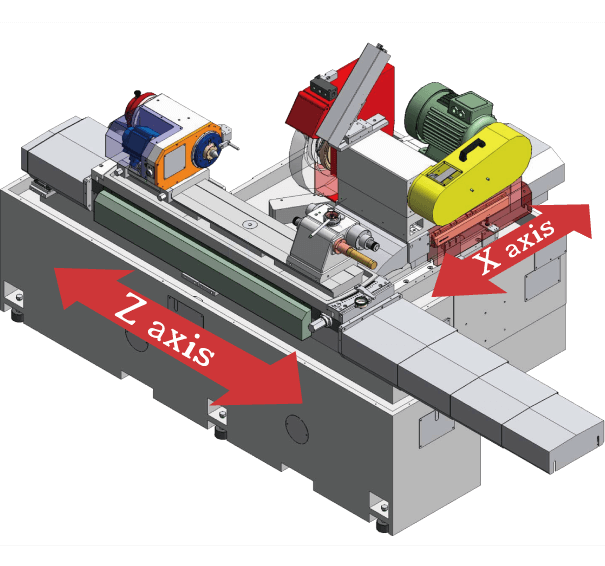

Feature

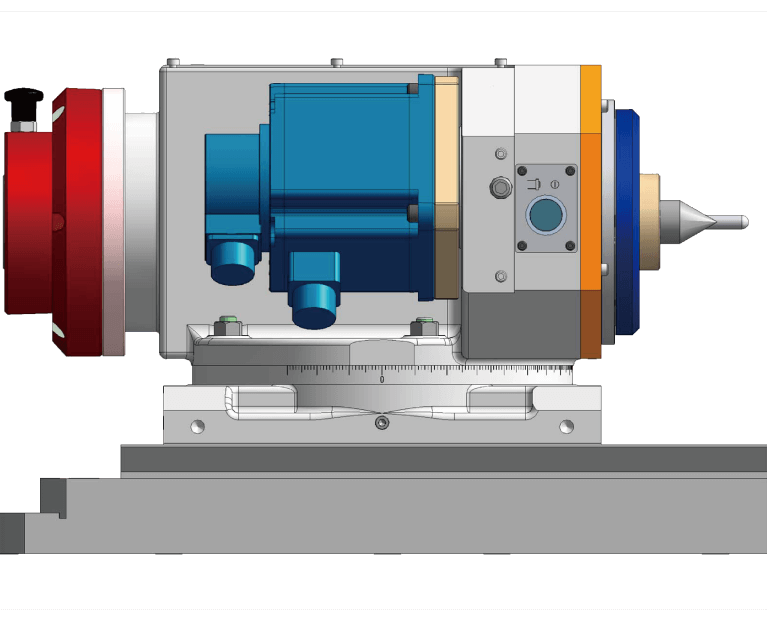

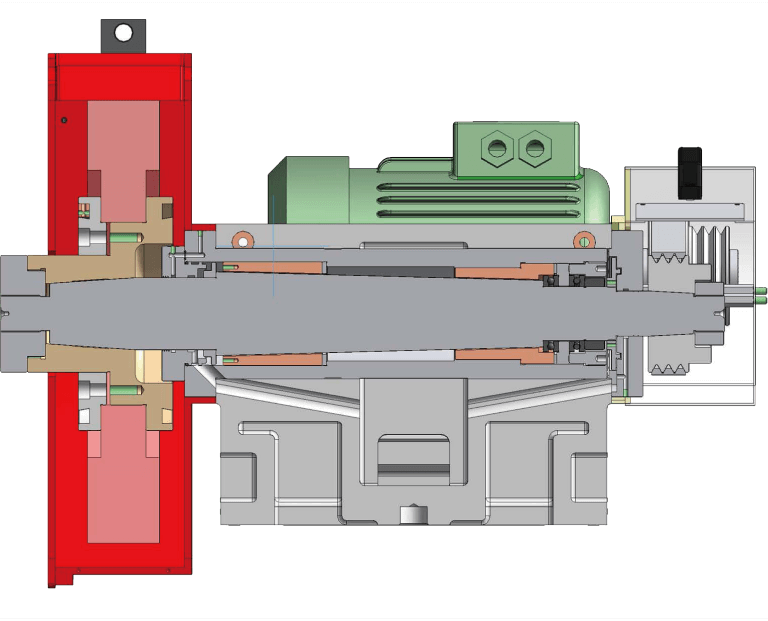

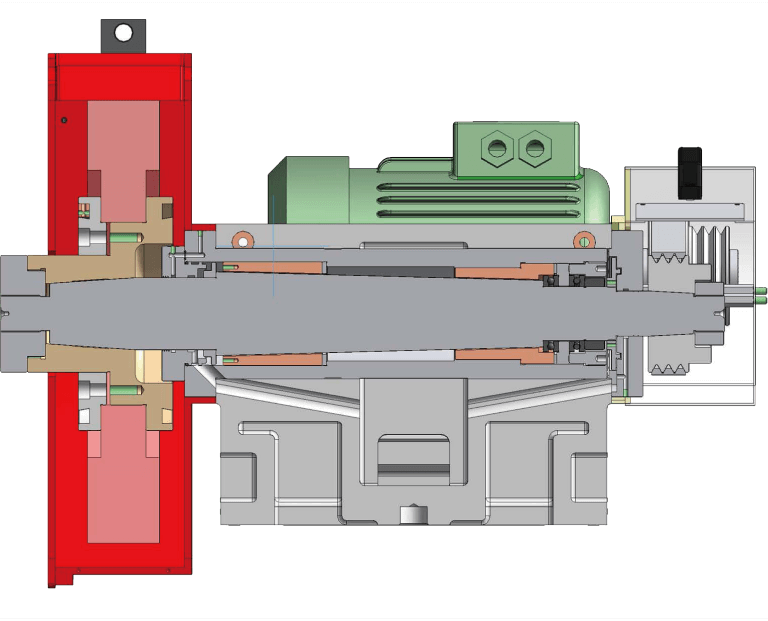

Work Head

NN bearing designed work spindle offers heavy duty load capacity, optimal rotation accuracy, and high rigidity. The servo motor drive offers steady speed and torque during the grinding operation. A positive air purge system keeps grinding swarf and coolant out of the work head, thus it prolongs its life.

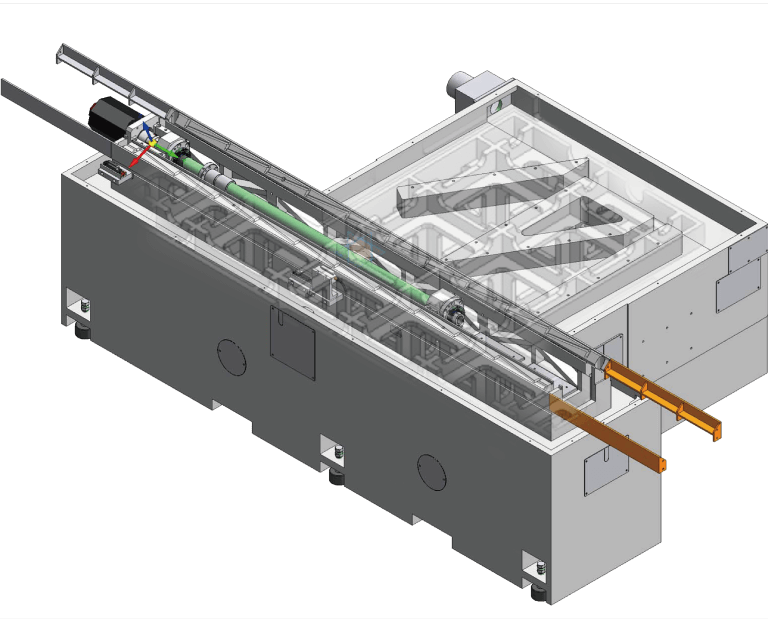

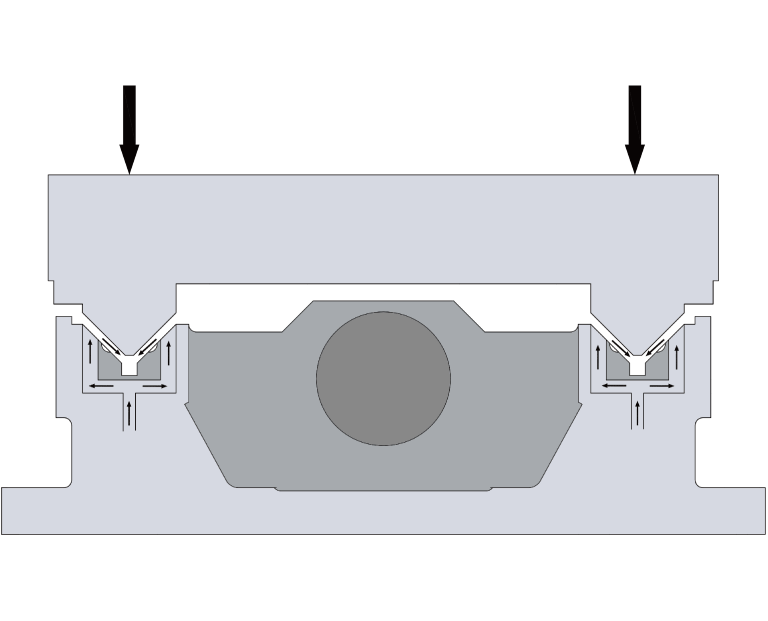

Rigid Machine Base

The machine based is designed to ensure the table is fully supported on both ends. The heavily ribbed box-type base is made of Meehanite casting, providing excellent rigidity and stability of the machine.

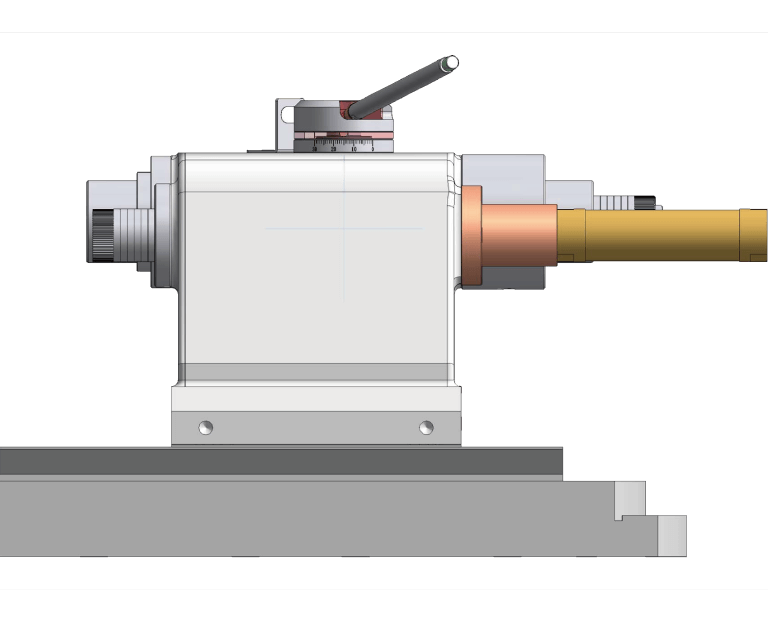

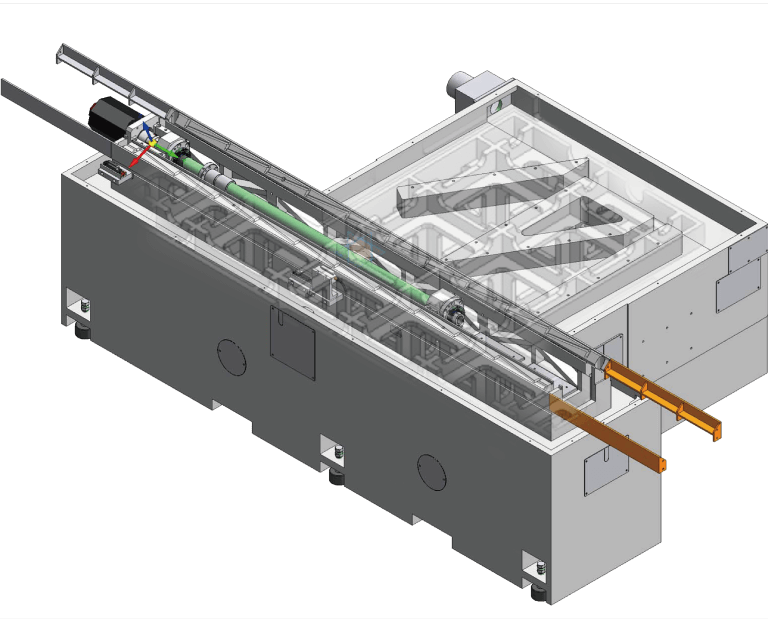

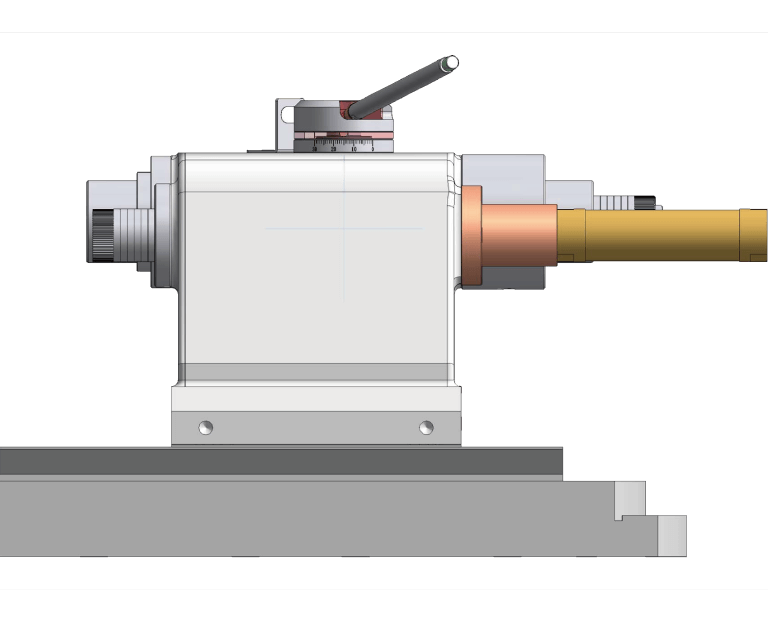

Tail Stock

A coolant nozzle is installed on the top of the tailstock for cooling the center tip. An air floating devise allows for smoother movement and protection of the table.

- An optional tailstock quill travel of 75mm helps to load/unload the workpiece with ease. The quill is oil-bathed to ensure smooth movement.

- An optional tailstock taper adjustment feature allows the operator to easily adjust for taper error. Features

Wheel head Spindle Bearing Options:

- Standard - Contact Bearing Type Spindle is easy to maintain, environmentally friendly and minimizes thermal growth issues.

- Optional - Hydrodynamic Babbit Bearing Type Spindle applies SNCM220 super alloy steel with multiple heat treatments makes the surface hardness of spindle up to HRC 62. These features ensure maximum cutting capability and best part finish performance in the grinding operation.

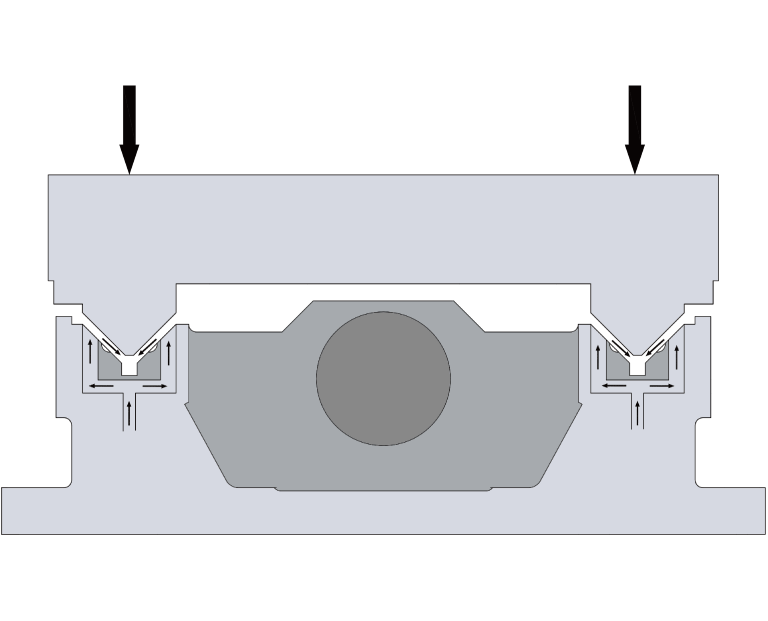

X-axis Guideway

The hand scraped Double V guideways provide maximum support to the wheel head for greater stability and grinding capacity. This design insures superior accuracy over the life of the machine.

Rigid Machine Base

The machine based is designed to ensure the table is fully supported on both ends. The heavily ribbed box-type base is made of Meehanite casting, providing excellent rigidity and stability of the machine.

Sample title 02

Tail Stock

A coolant nozzle is installed on the top of the tailstock for cooling the center tip. An air floating devise allows for smoother movement and protection of the table.

- An optional tailstock quill travel of 75mm helps to load/unload the workpiece with ease. The quill is oil-bathed to ensure smooth movement.

- An optional tailstock taper adjustment feature allows the operator to easily adjust for taper error. Features

Tail Stock

Wheel head Spindle Bearing Options:

- Standard - Contact Bearing Type Spindle is easy to maintain, environmentally friendly and minimizes thermal growth issues.

- Optional - Hydrodynamic Babbit Bearing Type Spindle applies SNCM220 super alloy steel with multiple heat treatments makes the surface hardness of spindle up to HRC 62. These features ensure maximum cutting capability and best part finish performance in the grinding operation.

X-axis Guideway

The hand scraped Double V guideways provide maximum support to the wheel head for greater stability and grinding capacity. This design insures superior accuracy over the life of the machine.

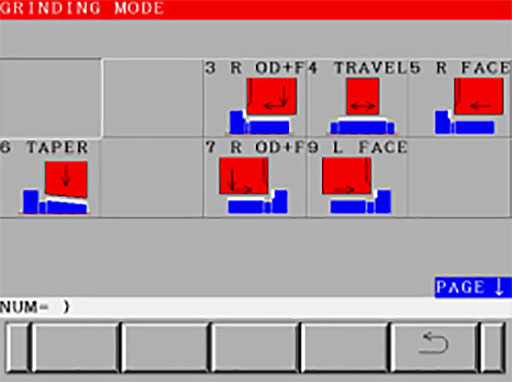

Control Option

anuc Control G-code & Macro program (Standard)

Conversational program for Fanuc (Option)

Mitsubishi M80 conversational program (Option)

Mitsubishi M80 conversational program (Option)

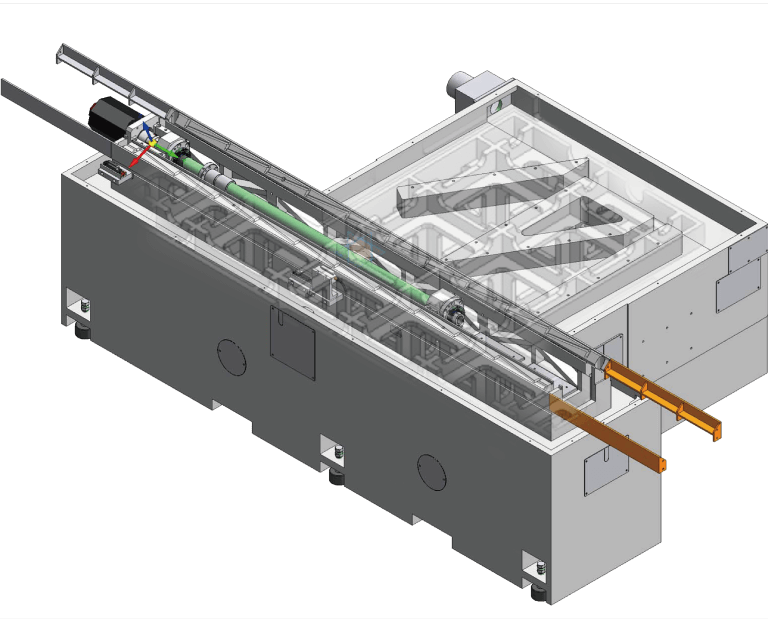

Grinding Example

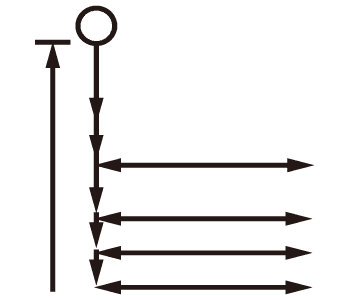

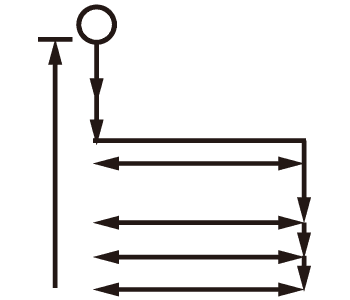

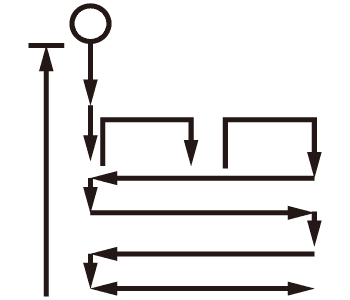

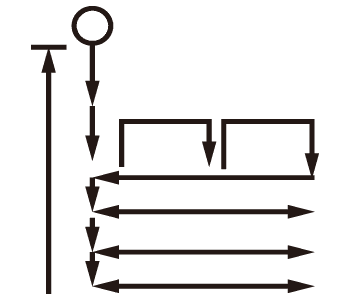

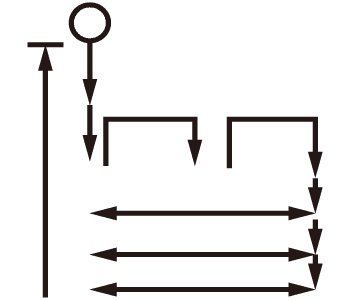

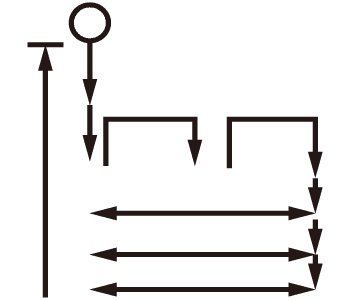

Grinding Cycle

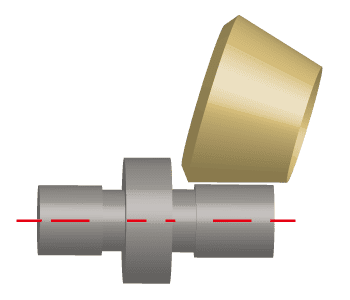

1. Plunge grinding

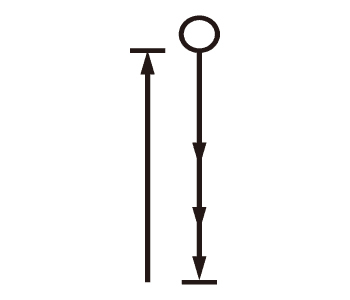

2. Traverse grinding

Both sides feed

LHS feed

RHS feed

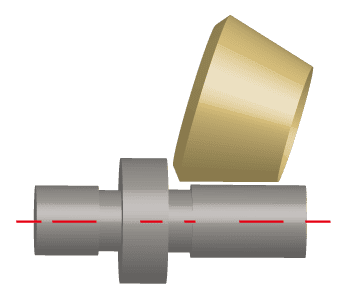

3. Plunge

Both sides feed

LHS feed

RHS feed

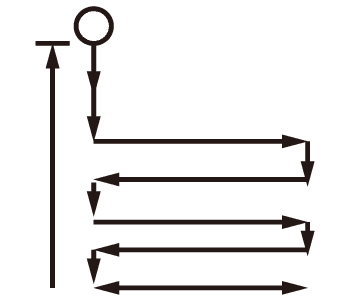

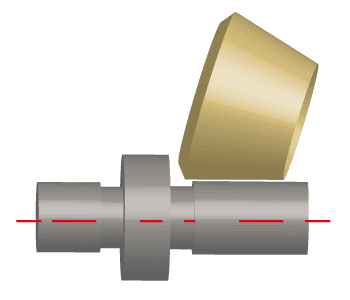

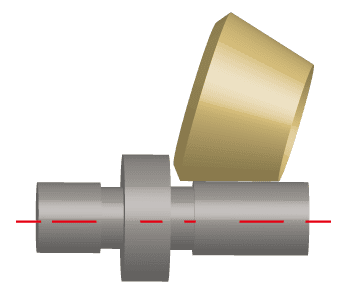

4. OD +End Face Grinding

Specification

Accessories