Please Chooese

Feature

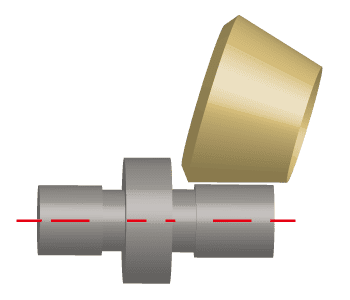

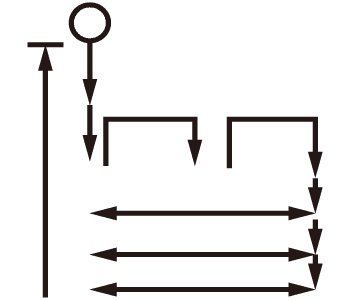

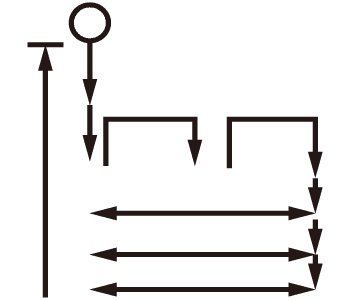

Grinding Cycle

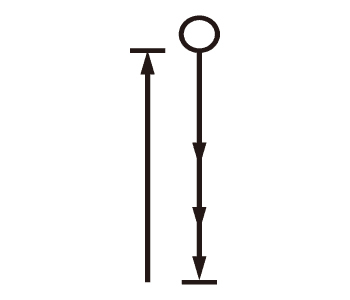

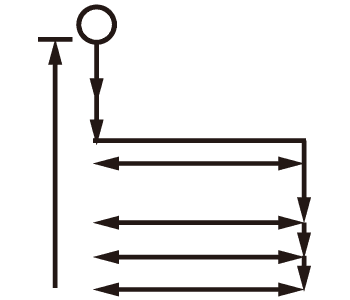

1. Plunge grinding

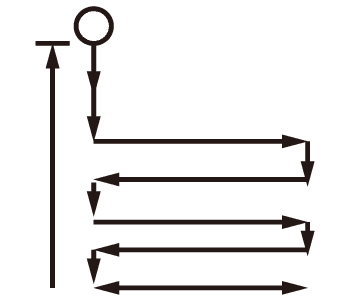

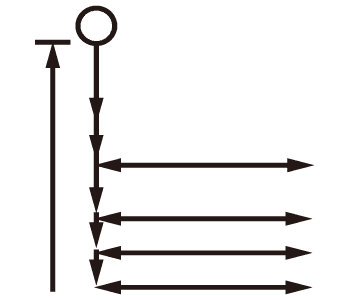

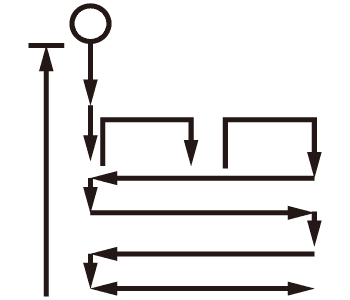

2. Traverse grinding

Both sides feed

LHS feed

RHS feed

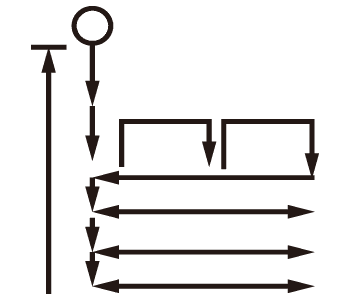

3. Plunge

Both sides feed

LHS feed

RHS feed

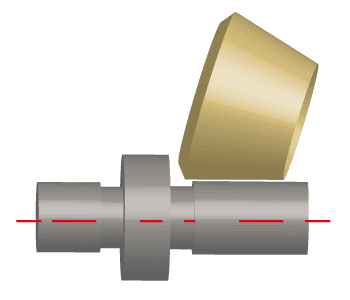

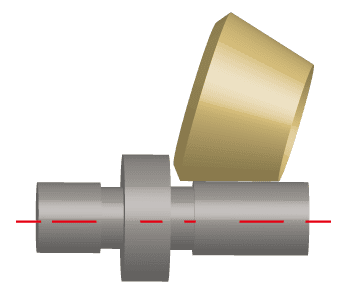

4. OD +End Face Grinding

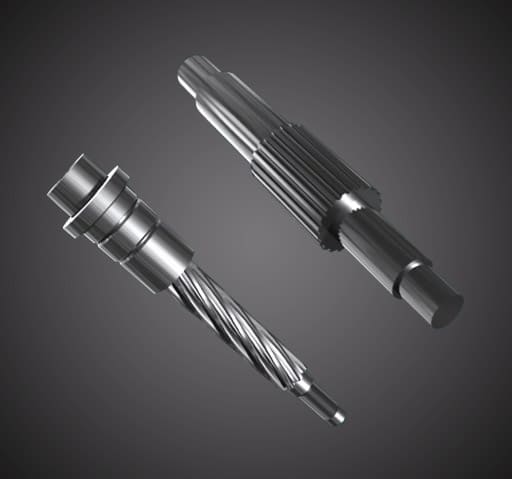

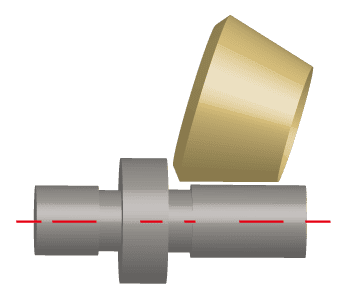

Grinding Example

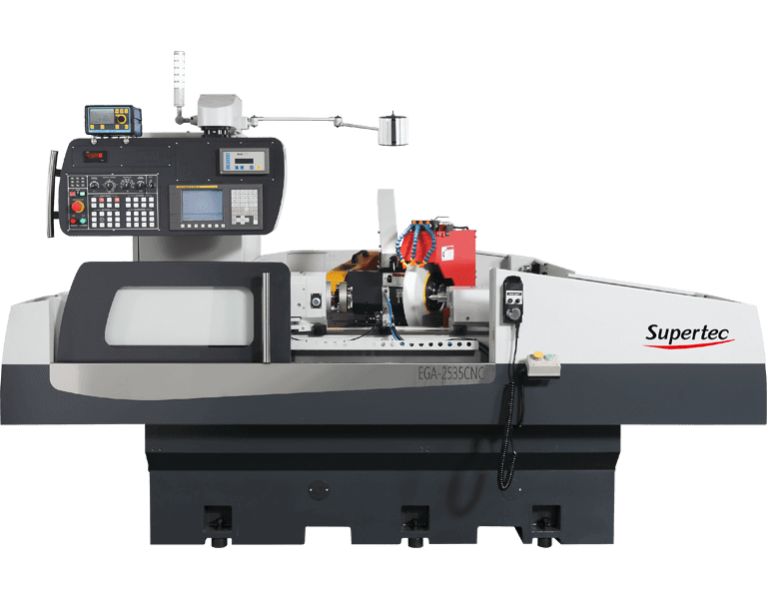

Specification

Accessories

Standard Accessories

Infinite variable workhead w/servo motor

Diamond Dresser and Stand

Automatic wheel speed change (15 steps)

Carbide tip center

X Axis Heidenhain linear scale (resolution 0.05 um)

Levelling bolts and blocks

Operation manual and part lists

Fanuc CNC Controller (Oi TF)

Grinding Wheel + Wheel Flange

Standard oil cooler (cooling fan)

Standard coolant tank 140L

MPG handwheel 2 Axes control

LED working light

Tools and Tool Box

Electricity cabinet w/ heat exchanger

Semi-enclosed splash guard

Wheel Extractor

4-color indication signal light

Optional Accessories

Dynamic balancing system (SBS)

Hydraulic tailstock (w/ foot pedal)

Z Axis Heidenhain linear scale (resolution 0.05 um)

Grinding wheel dynamic balance system

Wheel spindle lubrication oil cooler for hydrodynamic spindle

Gap & crash control device

Workhead spindle adjustment arbor

Auto gauging device

Spare grinding wheel flange

FANUC 0i-TF iGrind program

Mitsubishi controller (M80) iGrind program

Electrical cabinet air conditioner

Interanl grinding attachment (for EGP series only)

Workhead upgrade to MT5 (not suitable for 25 series)

Tailstock upgrade to MT5 (not suitable for 25 series)

Touch probe

Transformer

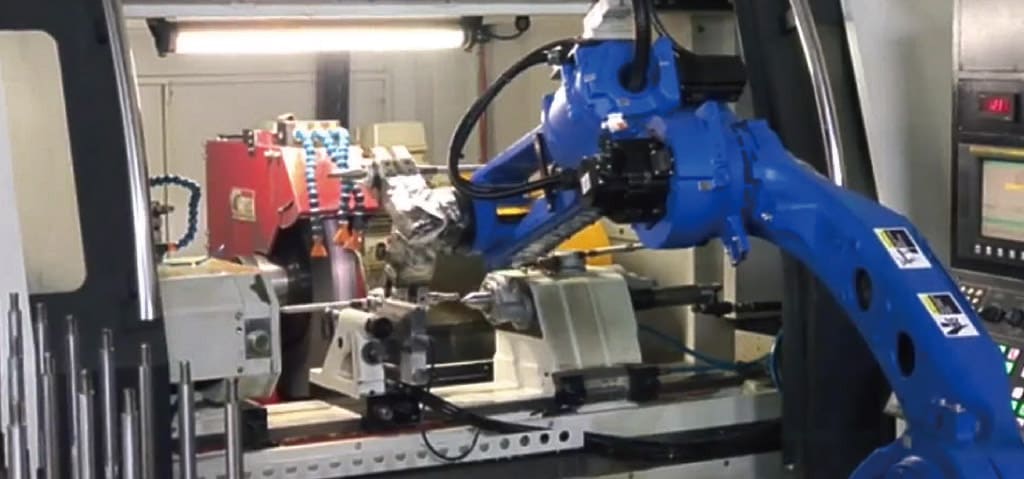

Workpiece cattier

Full-enclosed splash guard

Steady Rest

3-jaw scroll chuck

4-jaw scroll chuck